Guest article by Christian Erickson of Qnect - Connection Engineering and Design Software

“This nation should commit itself to achieving the goal, before this decade is out, of landing a man on the Moon and returning him safely to Earth.”

~ President John F. Kennedy May 25, 1961

That was a big goal. We know the outcome. Goal reached.

Another big goal in the building and construction was recently announced. Specifically in the structural steel sector - a growing and important part of any project.

This goal, announced by the American Institute of Steel Construction (AISC) - on September 30th during the 2019 Steel Day celebration states that through their work and others that they will be “increasing the speed by which structural steel buildings and bridges can be designed and constructed by 50%, by the end of 2025.”

Photo credit: Photo by Dakota Roos on Unsplash

2025? That’s only 5 years and a couple of months from now... not a long time away. For some steel folks, this will seem like a lofty goal. Some will consider this goal up there with the man-on-the-moon goal.

Knowing the brains (and there’s a lot of brainpower at AISC) behind this initiative, we know they would not enter into this lightly. They believe this can and more importantly that it should be done.

In addition to human brainpower, new technologies also play a key role in achieving this target goal. As a matter of fact, new construction innovations have skyrocketed over the past several years positively influencing the speed in which construction projects are completed.

When it comes to steel construction two software applications stand out as agents of change – Qnect and Bluebeam Revu PDF software.

Bluebeam Revu

Get a 30-day free trial of Bluebeam Revu

Bluebeam, part of the Nemetschek family since 2014, is a digital player making the communication of projects more efficient.

Their solution delivers innovative markup and collaboration technology. According to their website, their flagship product, Bluebeam Revu, “keeps teams on the same page through the design process, helps move the project forward during construction, and preserves important project data through completion and beyond.”

One way Bluebeam improves the process of structural steel construction is through the creation of custom tools. Revu allows users to make custom markup and takeoff tools, save them in a custom Tool Chest and share them amongst all companies involved in the project.

This standardization greatly speeds up the construction process and improves communication.

Qnect - Connection Engineering Software

Qnect, a SaaS connection design and engineering tool, will play a major role in this as well as their forward-thinking and innovative customers.

Qnect helps you optimize steel construction connections.

Get Started with Qnect for Free

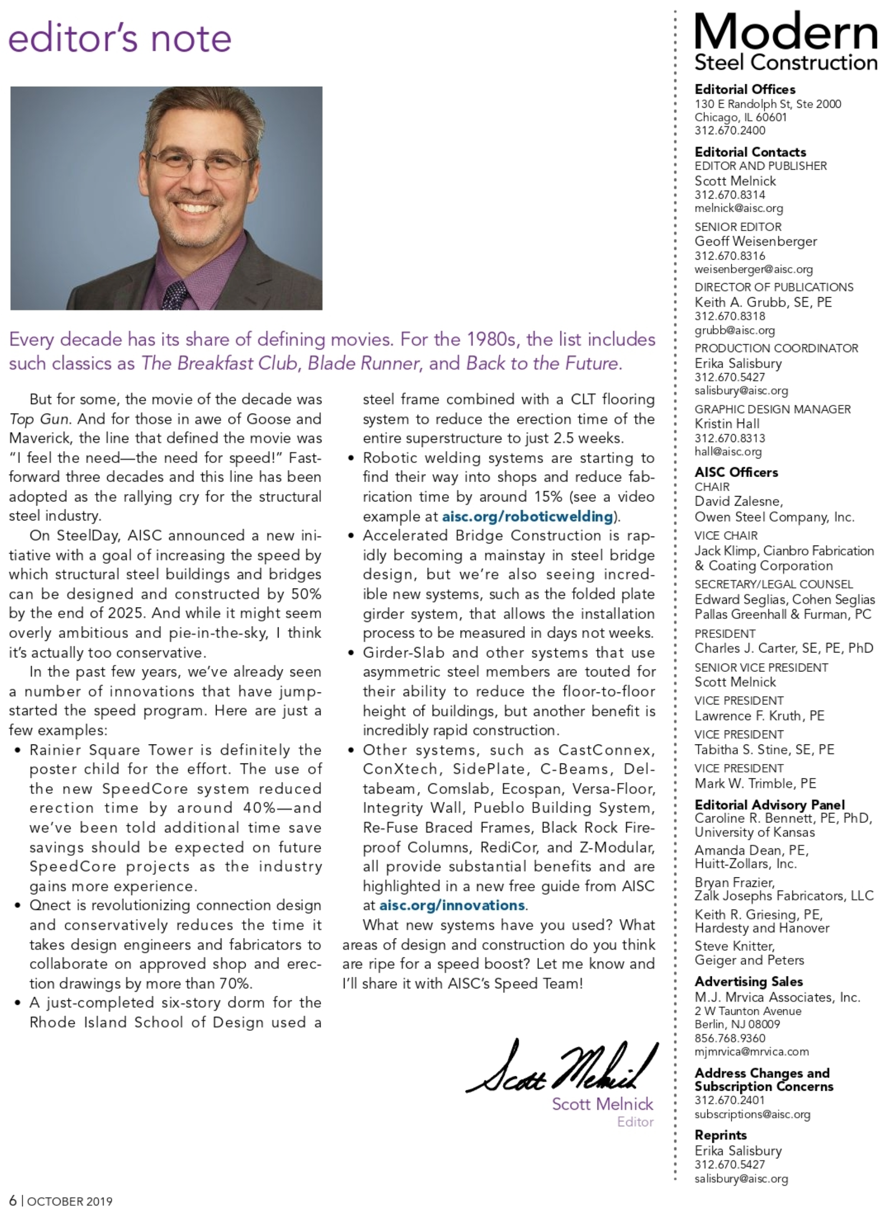

In the initiative article, MSC Editor Scott Melnick writes:

“Qnect is revolutionizing connection design and conservatively reduces the time it takes design engineers and fabricators to collaborate on approved shop and erection drawings by more than 70%.”

The Qnect team talks constantly with very progressive and forward-thinking steel leaders. They also think this goal can be achieved within the five-year challenge.

This includes Sang Chin, President, SNC Engineering, Inc who has said,

"I believe it [Qnect] saves us over 30% on modeling time in this project...This project really proves how much advantage that we can get by using Qnect."

What we are seeing at Qnect is that technology contributes to increased speed during the design phase and beyond. Less modeling time means faster time to produce shop drawings. We also know that schedule drift can wreak havoc on a project and Qnect prevents this from happening.

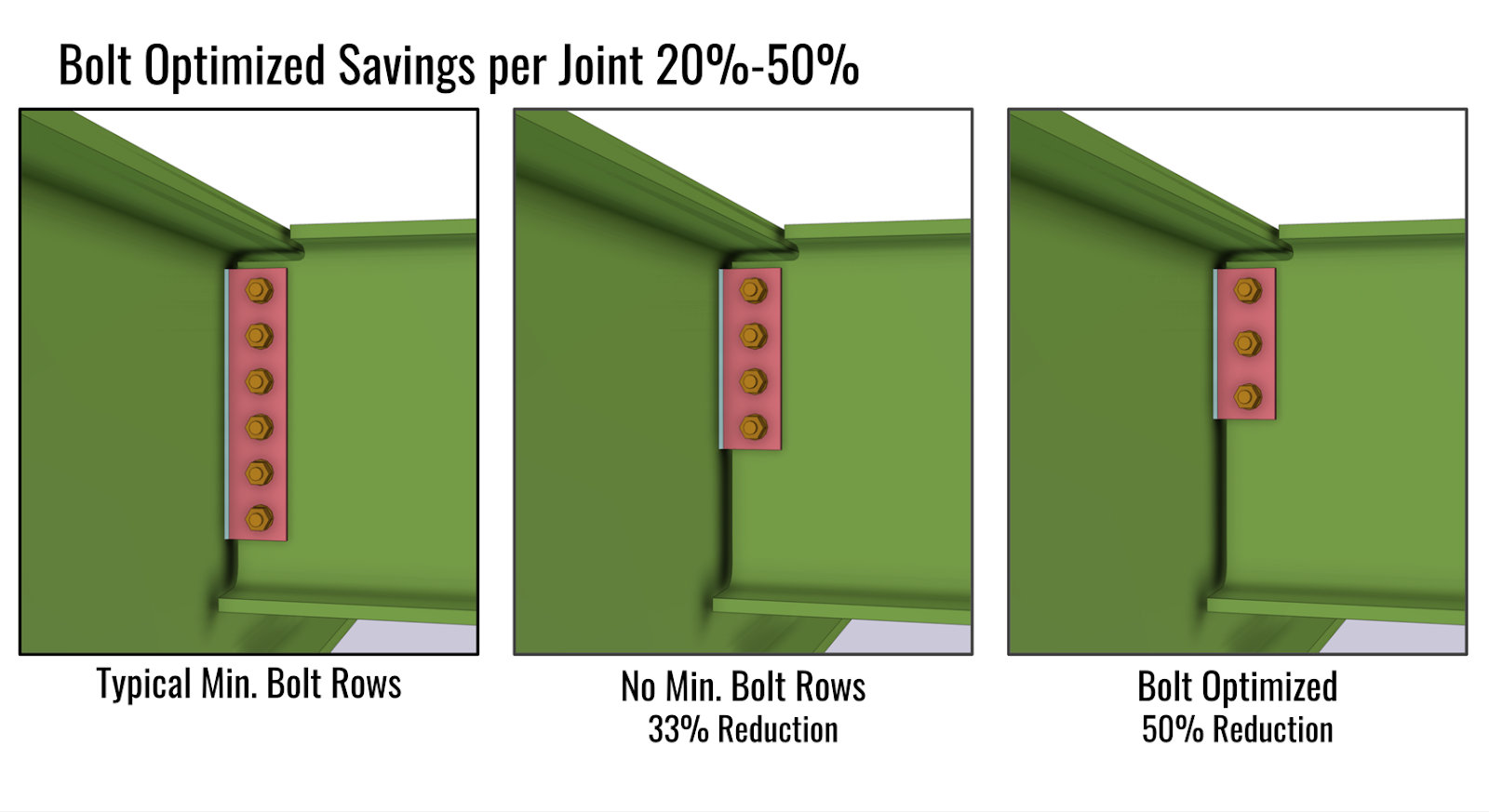

Some numbers that Qnect recently shared in our October webinar include:

- Shop Drawing Production: Preventing schedule drift

- Qnect creates buffer time to deal with changes and mitigate schedule drift. Eg: A16-week schedule creates a buffer time of 3 to 5 weeks.

- One Station Fabrication

- Qnect will use its patented software and proprietary process to manage end connections to maximize the number of pieces that need one station fabrication versus two.

- Reducing time to fabricate (and associated cost)

- Qnect reduces time to fabricate by reducing bolts and holes to drill anywhere from 20% to 50%

What makes the mention in MSC so satisfying is the data that Qnect has to back up the “revolution.” We welcome you to reach out to us and allow us to show you how to make it work for you.

American Institute of Steel Construction and MSC (Modern Steel Construction).

Article written by Christian Erickson - Qnect

Christian Erickson, Qnect’s Director of Global Marketing and Sales, attends conferences and events and shares his observations on industry trends in the Qnect news blog and with partners.

Connect with Christian on LinkedIn - www.linkedin.com/in/ericksonchristian

Learn more about Qnect's innovative technologies - https://www.qnect.com/

Qnect has built a game-changing solution for faster, cheaper, better connections.

November 12, 2019

Comments