[ Free Consultation ] Are you interested in exploring new CAD plotter options but do no know where to start? Get help from our top tech experts in a free consultation call.

Click Here to Schedule Your Free Consultation Call

Article updated in 2023

Blueprints are a classic historical icon of the construction industry. For some more seasoned AEC professionals, blueprints bring back nostalgic memories. For other, younger people, a blueprint (or blueline) drawing may be best viewed in a museum, not at a job site.

But, the fact remains, printed construction plans are still used regularly (I know this because companies still buy a lot of plotters from us). And, while digital files and applications are wonderful to work with, having a set of paper plans onsite is still valid.

This still leads companies to purchase new plotters or MFPs. And when exploring options, you have probably wondered, “Should I get an inkjet or a toner plotter?”

This question has forced me to examine everything known and preached for the past 20 years in favor of toner technologies. After much thought and analysis, let's just say he future is bright, colorful, and primed for inkjet.

The Toner Plotter Legacy

Back then, it was easy to justify investing in a toner blueprint printer, meaning a wide-format or multifunction system. They are printing beasts designed to print thousands of square feet per month. The sheer volume produced by these machines validated expenses through economies of scale.

Toner-based systems have been the go-to for years, meeting industry regulations with their consistent quality. Their printing pages per minute and robust paper trays could handle large project volumes, ensuring you meet tight deadlines.

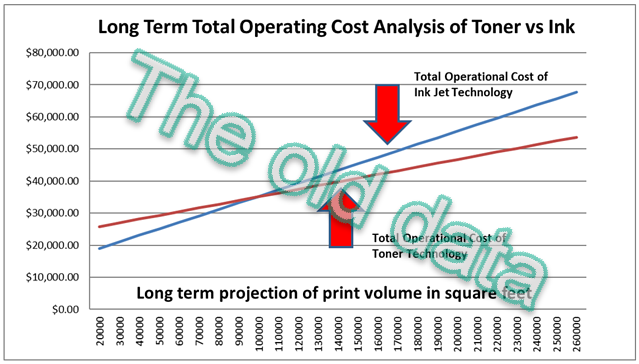

The ROI (return on investment) could happen quickly – sometimes in months. Typically, the break-even point happened at 2,000 square feet per month. Therefore, it was typical for a toner plotter to be less costly in the long run.

Inkjet Plotters

The abundance of inkjet plotters installed nationwide showcases the popularity of these systems. After all, they are less expensive than toner machines, are easy to use, and allow you to print in full color.

Historically, the cost of inkjet printing was an obstacle; it was considerably higher than toner. However, new models are more economical and offer custom solutions tailored to your project's needs.

It was safe to estimate that inkjet printing costs per square foot compared to the $0.095 per square foot toner. This assumes all printing costs – ink or toner, paper, and a service contract fee.

Given these numbers, the price delta could profoundly impact a higher volume. But, as mentioned earlier, people are not printing as often. Today, a single set of plans is sufficient when ten sets were needed for the same job in the past.

Tides have turned to ink technologies. In addition to lower demand, the actual cost of printing with ink has fallen significantly. Today, the operational cost of inkjet printing is usually less than $0.10 per square foot (for line drawings) – which is now less than the average cost of printing with toner.

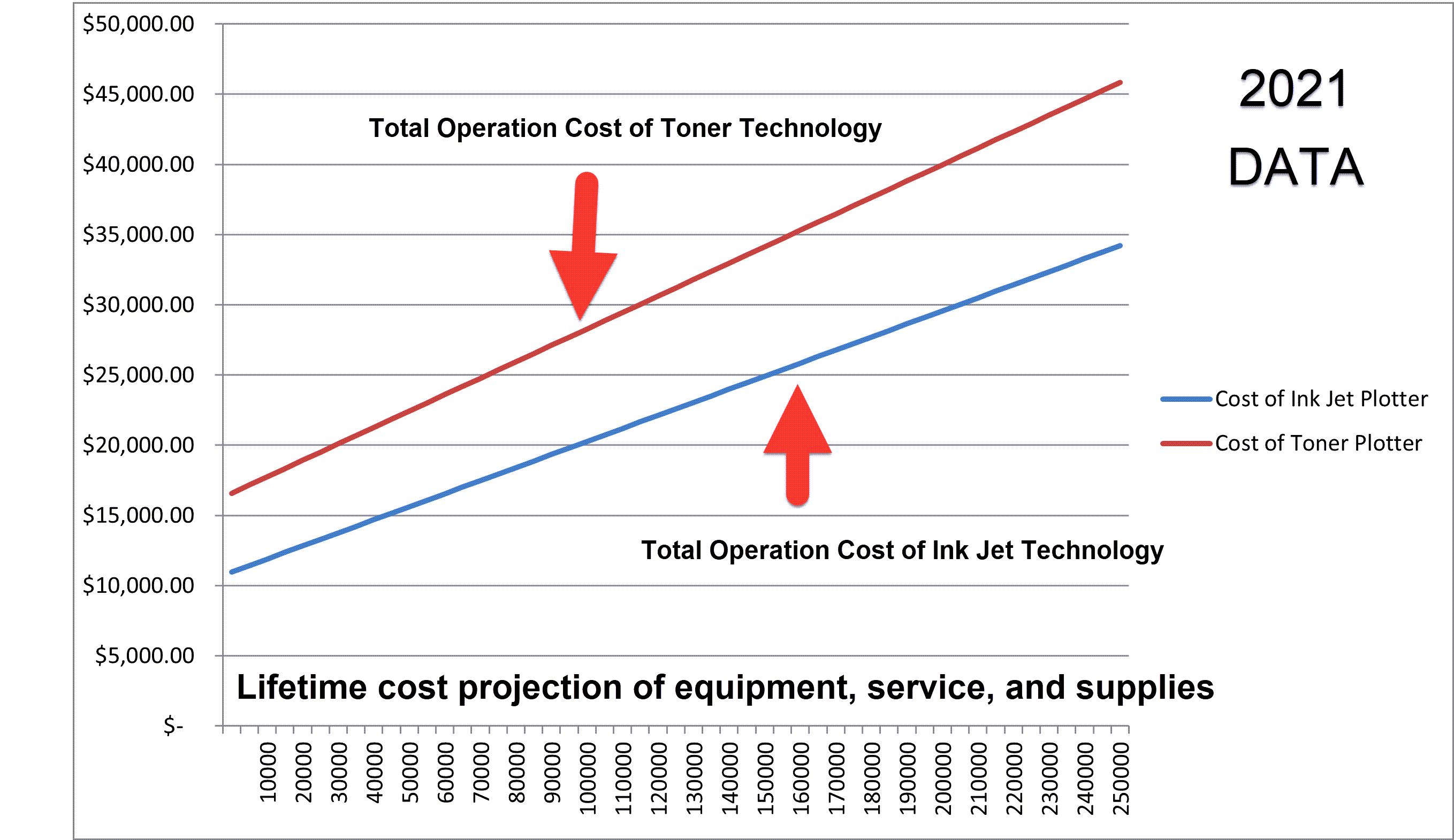

How the data was compiled:

-

Total Cost of Operation for both systems: equipment, service contract, and supplies

-

Equipment market prices were used for the analysis (PlotWave 3000: $16,000, Canon TX-3100 MFP: $10,500)

-

Both wide-format printer systems are configured as 2-roll multifunction units including printer, scanner, and controller PC

-

As you can see, there is no longer a split where it is more cost-effective to use a toner plotter. Inkjet systems have improved so much that the lines no longer cross. Plus, with TAVCO's solid after-sales support, you're making a future-proof investment.

Based on our analysis, the operational costs of ink jets tend to hover around $0.093 per square foot, while the cost of LED toner averages $0.117 per square foot. (This includes all monthly service charges and printing supplies).

Today's inkjet plotters, like the Canon iPF and the HP DesignJet, offer vibrant color print quality and wireless network capabilities. They're perfect for printing directly from mobile devices. Also, the paper size options have expanded, accommodating everything from standard cut sheets to rolls.

At least with Canon wide-format equipment, an inkjet plotter can produce 4 D-size (24x36) sheets per minute. That is crazy! Learn more: Check out the new TZ-30000.

Ready to make a change?

Durability

Historically, inkjet plotters are only designed to last a few years. This concept is challenging for some people to accept, but it is legit. Research this, and you'll find that inkjet plotters, regardless of manufacturer, usually do not offer an extended service plan past three years.

On the flip side, the price for a replacement ink jet plotter today is less than half of what it used to cost. So, buying a new ink jet plotter or MFP every few years is justifiable to keep up with the technology changes.

But that is not to say you can’t get more life out of them. I have plenty of customers who have used their inkjet machine for over 5-6 years or longer, in some cases.

Toner-based plotters for blueprints, on the other hand, are much more durable systems that are made to last for many years. For example, the estimated life expectancy of a Canon PlotWave system is seven to ten years on average.

So, if you are comfortable purchasing a solution and using it for many years, a toner-based printer could still be justified.

Duty Cycles

Traditional ink jet plotters were not designed to handle large print volumes (duty cycle). However, many improvements have been made regarding the latest versions, and depending on the inkjet model, they can produce up to 10,000 square feet per month – which is a lot by today’s standards.

But, on average, the small entry-level units are only rated for about 3,000 square feet per month. TAVCO offers short-term demos or trials to help you understand the cost-efficiency of your specific workload. Anything more than that is considered “outside of normal operating parameters.” But given that most companies today only print about 1,500 square feet per month, the smaller duty cycles are not a problem.

Toner-based plotters, however, can easily handle many thousands of square feet of printing per month. For instance, the Canon PlotWave 7500 can produce 25,000+ square feet of monthly printing. That is 4,167 D-size sheets – a fantastic number by today’s standards.

Print Speed and Wi-Fi

Inkjets are now faster than ever. A big reason for this is the increased onboard processing power. Many units now have a powerful PC processor, more RAM, and an onboard Hard Drive to help spool prints.

Modern inkjets are not just about print quality. They also offer rapid printing pages per minute and seamless integration with Wi-Fi networks. This allows for easy printing from mobile devices, perfect for AEC professionals on the go.

HP PageWide - Single Pass Plotter Technology

A newer inkjet technology emerged in the past few years - a single-pass system. There are different names, Memjet and HP PageWide, but the process is the same.

Unlike standard ink jets that use a traveling print head, this new single-pass technology relies on a long, stationary print head that jets ink onto a traveling media underneath. Thus, the "single pass" of the print head over the print material.

If you haven't seen it, this type of printing is undoubtedly impressive. An inherent benefit of single-pass printing is speed. Some of these machines can print up to 16 D-size pages per minute.

Additionally, manufacturers of single-pass printers are promoting a lower operational cost of these systems but be warned these new devices are not for everybody. There are some limitations to consider.

They are large - Most high-speed ink jet systems are designed as commercial printers and unsuitable for traditional office environments. Their excessive mass can make them difficult to install, presenting challenges regarding doors, tight turns, and standard-size elevators.

They are heavy - Generally, single-pass printers weigh more than 1,000 pounds. This can be challenging for locations that do not have concrete or reinforced floors.

High speed may not be necessary - Realistically, most Architectural and Engineering offices today average 1,500 square feet per month of printing output.

This figure has shrunk over the years as companies digitize some of their workflows and utilize large format printers for more color-centric duties. So, as the demand lowers, does the need to print many sheets quickly?

Mobile and Wireless Networking

The convenience of printing from mobile devices via a wireless network is something that modern inkjet plotters, like the HP DesignJet, offer out-of-the-box. This feature seamlessly integrates with your existing systems, ensuring minimal disruption to your project timelines.

Quality, Reliability, and Vendor Relationship

HP DesignJet and other TAVCO-supported inkjets are unparalleled regarding print quality and reliability. Our strong vendor relationships ensure you receive a product and a reliable partner for your long-term AEC needs.

Summary

Many changes have occurred in the AEC and wide-format plotter industries in just a few years. Lower print demands, the need for more full-color drawings, and better technology have completely disrupted the traditional models.

In the past, LED toner plotters were championed as far superior to their inkjet counterparts. However, that is no longer the case. Today’s inkjet systems are powerful units that can print larger volumes quickly and inexpensively.

Ultimately, companies need to be smart about their wide-format technology investments and consider all the factors before deciding on a system.

What is your technology of choice?

February 2, 2023

Comments